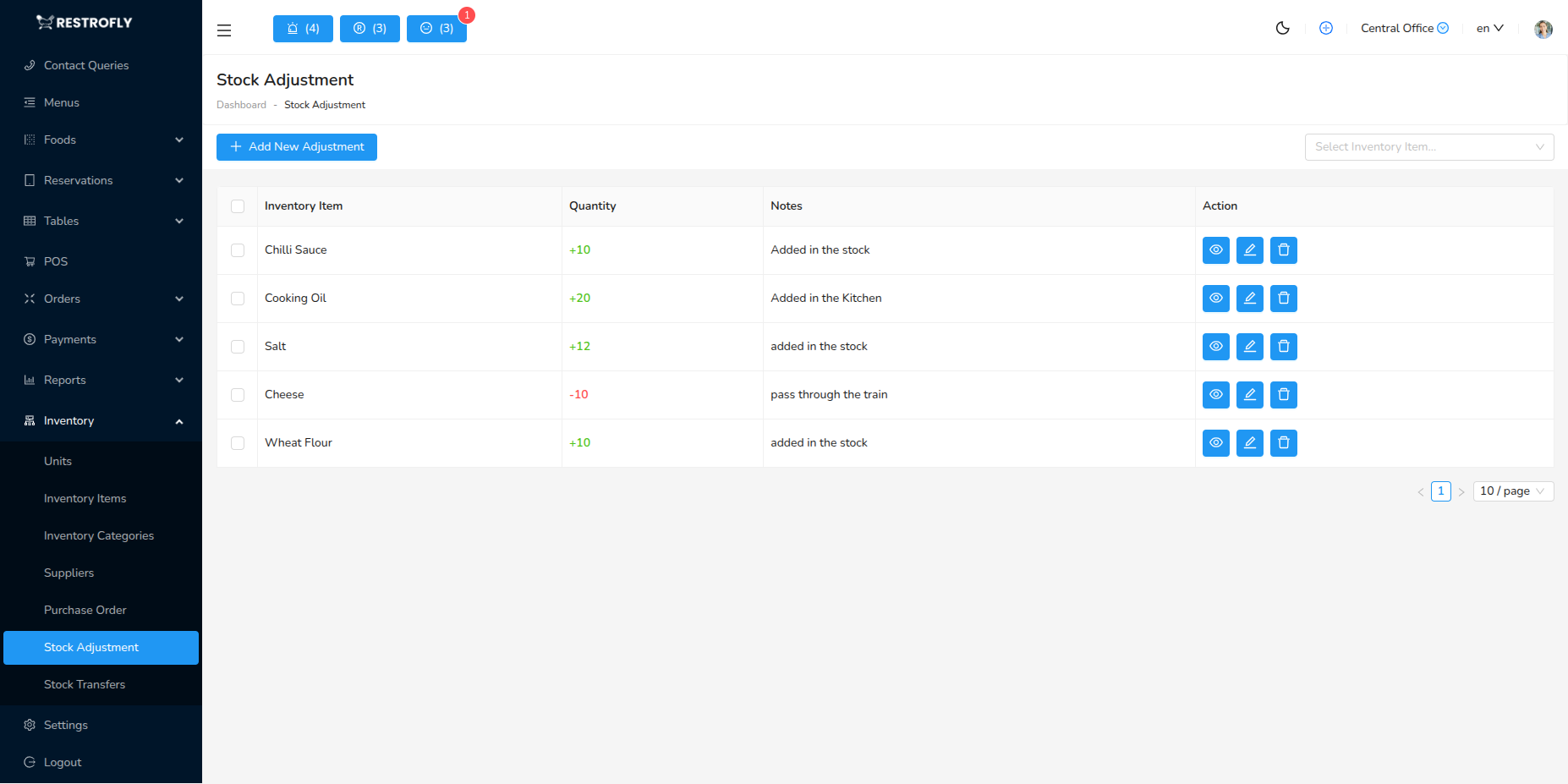

Stock Adjustment

Adjust inventory levels for waste, damage, corrections, etc. Navigate to Inventory → Stock Adjustment to record adjustments.

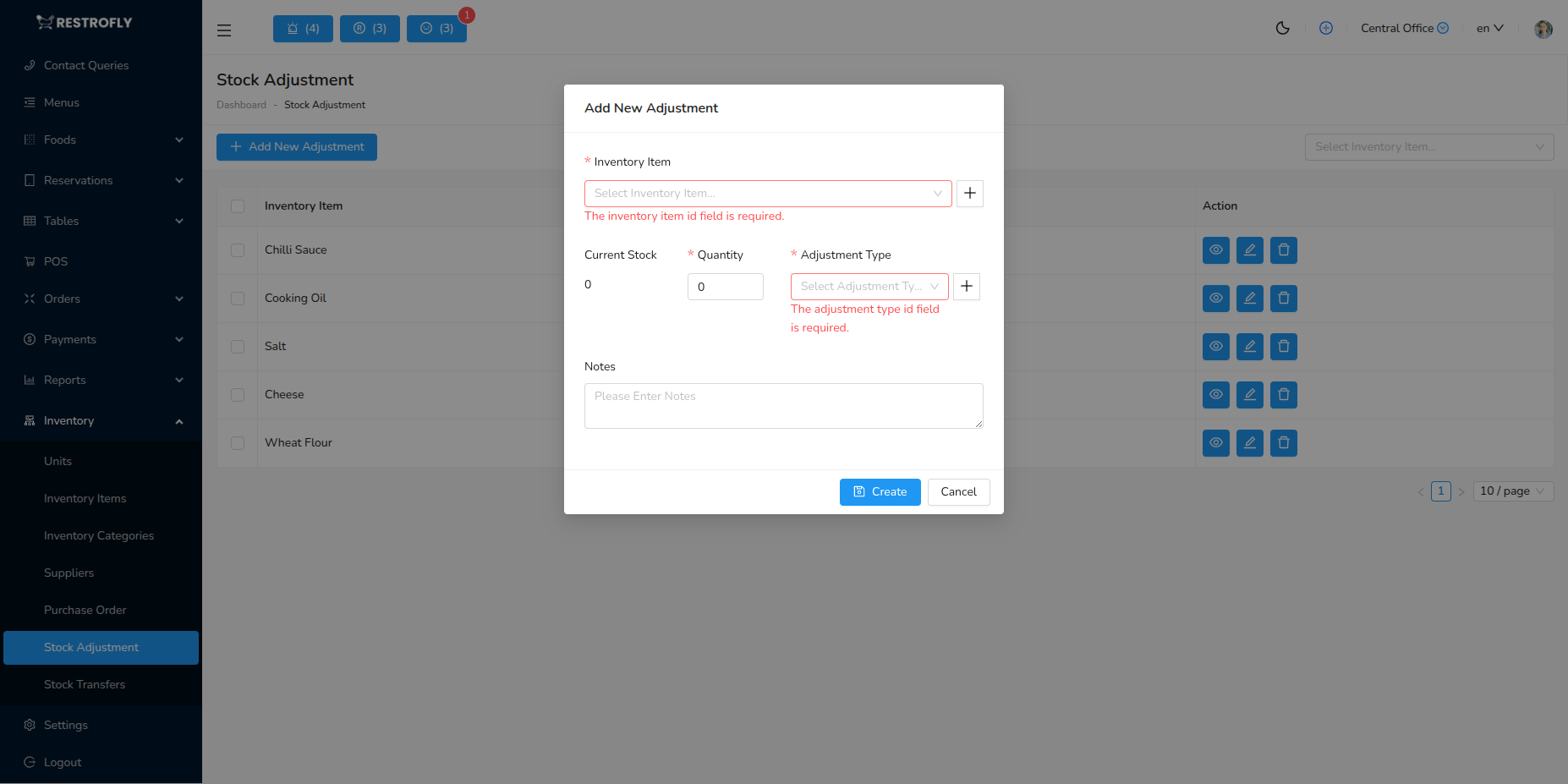

Creating Stock Adjustment

Adjustment Type: Addition or Reduction

Item: Select inventory item

Quantity: Amount to add or subtract

Reason: Waste, Damage, Theft, Count Correction, Expired, Spoilage, Other

Notes: Detailed explanation

Date: When adjustment occurred

Adjustment Reasons

Waste: Food waste during prep, trimmings, overproduction

Spoilage: Items gone bad, expired products

Damage: Broken items, damaged packaging

Theft: Missing inventory

Count Correction: Physical count differs from system, reconciliation

Sampling: Tasting, quality checks

Promotion: Free samples, giveaways

Best Practices

Document Everything: Always note reason for adjustment, maintain audit trail

Regular Counts: Physical counts reveal need for adjustments, do weekly or monthly

Investigate Large Adjustments: Significant discrepancies need investigation, identify root causes

Reduce Waste: Track waste patterns, implement waste reduction strategies

Training: Train staff on proper portioning, storage, handling to reduce waste

Frequent Adjustments

Frequent stock adjustments indicate problems: theft, poor portion control, inadequate storage, or system errors. Investigate and address root causes.